Uni turns to mask production

Expert teams at the University of Newcastle have come up with new methods for the rapid production of desperately needed medical equipment.

Expert teams at the University of Newcastle have come up with new methods for the rapid production of desperately needed medical equipment.

Around the world, there are dire shortages of medical-grade resources to treat COVID-19 patients, with personal protective equipment (PPE), ventilators and respirators in notably short supply.

Now, a working group from a range of disciplines has shown exceptional initiative in aiding these shortages.

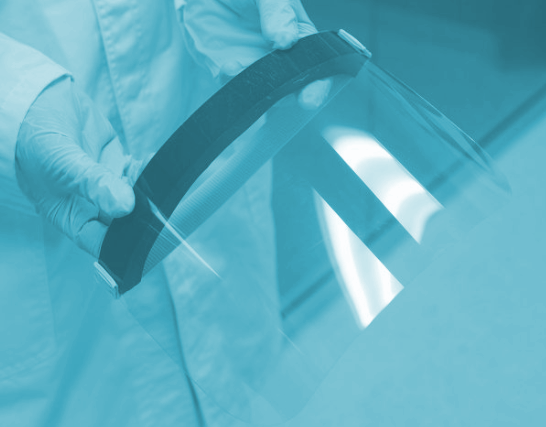

The team of physicists, engineers, designers and health workers are producing face shields made from a piece of PET plastic held in place by an elastic headband.

“The chosen design is simple and fast to assemble, so we’re able to generate hundreds a day which are already being distributed in our region and beyond,” said Professor Paul Dastoor, Director of the Centre for Organic Electronics (COE) – the team responsible for manufacturing the face shields.

While the team was well-versed in the development and production of advanced medical devices, the rapid manufacture of medical PPE was not business as usual for them.

“We had stocks of PET available to us for use in the production of our printed solar panels,” Professor Dastoor said.

“As a result of the scoping work done by our colleagues, we were able to tap into the collective expertise of the University, connecting with fellow researchers to arrive at a prototype we knew we could manufacture rapidly.

“Industry partners were also quick to support the cause, with Guru Labels on the Central Coast laser cutting the PET in bulk and the Australian National Fabrication Facility team based at the University contributing to the build of the shield assembly line.

“The beauty of this kind of effort is, now we have a model we know addresses the needs of those on the ground, we’ve been able to collaborate to make the production process even faster. There’s truly a community rallying together contribute what they can in this crisis.”

Pro Vice-Chancellor Faculty of Engineering, Professor Brett Ninness, said the same team is working on a range of projects.

“From face shields; to 3D printed equipment; to novel tests for COVID-19; and the repurposing of existing drugs,” he said.

“As scientists and engineers, our responsibility is to try and solve some of the world’s greatest challenges, and right now, COVID-19 is it.”

Print

Print